Valve History

Valves have come a long way from their beginnings, almost 2000 years ago. Technological advancements and human knowledge have continuously allowed new and improved designs to emerge in the valve industry. Technological advancements are paired with the need for valves to be better suited for the applications as industries need

Valve Glossary

A reference tool to help users understand and clarify the meaning of specific terms and concepts within world of valves.

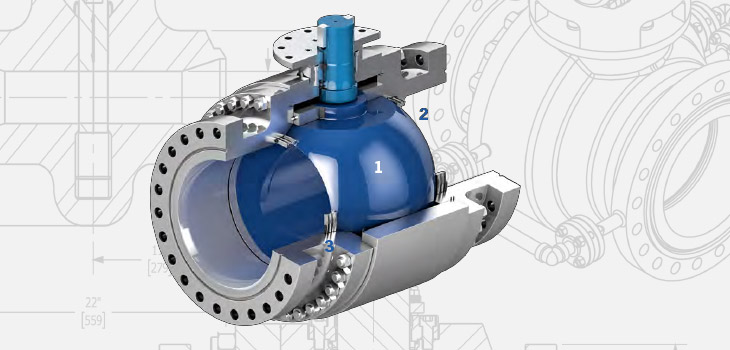

Bidirectionality in Isolation Valves

There are many types of valves used to isolate process flow. Each valve type has its own ability when it is fully closed and in isolation mode. The degree of tightness varies with valve type, make, media, differential pressure, temperature, and time in

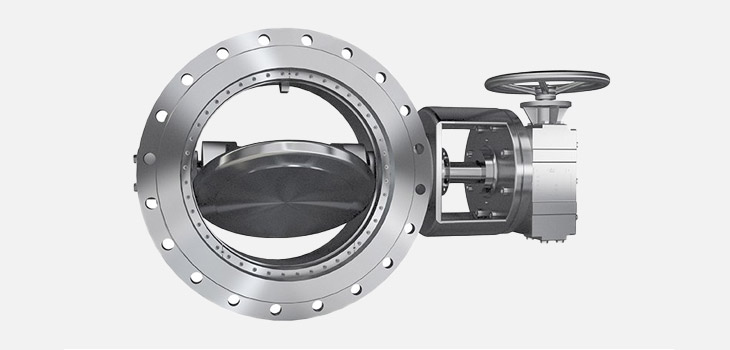

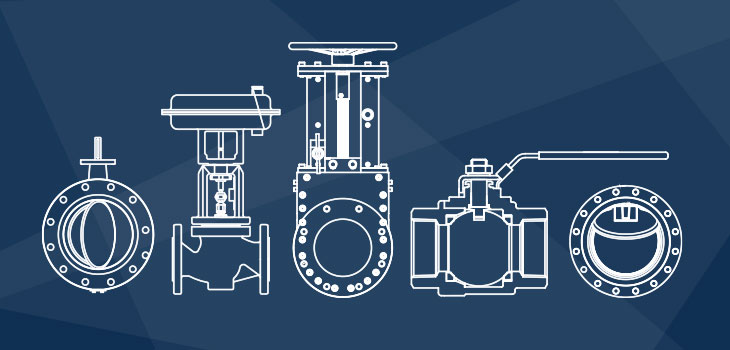

Butterfly Valves 101

A basic introduction to Butterfly Valves Butterfly Valves get their name from the Butterfly appearance of the disc and stem. The design consists of a round disc that is attached to a shaft rotating 90°. When the disc rotates to be parallel with

Butterfly Valves — Triple Offset Design

The unique triple offset of the valve means the seating is affected with almost zero friction. The disc lifts off the seat without dragging across the surface. Because of this feature, these valves could be placed through 500,000 cycles of operation without any

What is a Guided Shear Gate Valve and why is it a Severe Service Knife Gate Valve?

All valves perform a duty. Their ability to perform varies by valve type and internal design features and materials. In addition, knowledge and experience play a significant part in any successful installation. Accurate descriptions and consistent communication regarding the specifications of the valve

Six factors to consider when buying a Severe Service Valve

The term Severe Service Valve (SSV) is commonplace to the industrial valve industry. The problem is no one really knows exactly what it means. CGIS is in the process of establishing the exact definition. Once in place and approved by the Manufacturers Standardization

Allowable Leakage vs. Zero Leakage vs. Bubble Tight

Valve leakage is one of the main issues in industrial processes. Different valve leakage standards are specified by different organizations. Valves go through pressure tests which determine if they provide allowable leakage, zero leakage, or are bubble tight. Allowable leakage: Some valves have

The Building Blocks of Severe Service Valves (SSVs)

Most of us know when an application is severe. But what is it that makes it severe for a valve? Defining Severe Service Valves (SSVs) objectively is an important tool in attaining improved process control, safety, profitability, and environmental stewardship. SSVs can be

Defining Severe Service Valves

There is no clear or universal industry definition or mechanism to describe and accurately define severe service valves (SSVs) and separate them from general purpose valves. Yet, such a definition would allow the industry to benefit from improved process performance, increased profitability, safety,

An Introduction to Severe Service Valves

Severe Service Valves (SSVs) mean different things to different people. Until today, defining SSVs had little if any global agreement or recognition. That is about to change as the Manufacturers Standardization Society (MSS) has accepted an application to produce a Standard Practice of

Class 150 Does Not Equal 150 psig

Pressure-Temperature Ratings for Valves When it comes to valves, there are guidelines in place to protect workers and the environment from valve failures and leakage. In this example, we are talking about how much operating pressure a valve can withstand at a specific

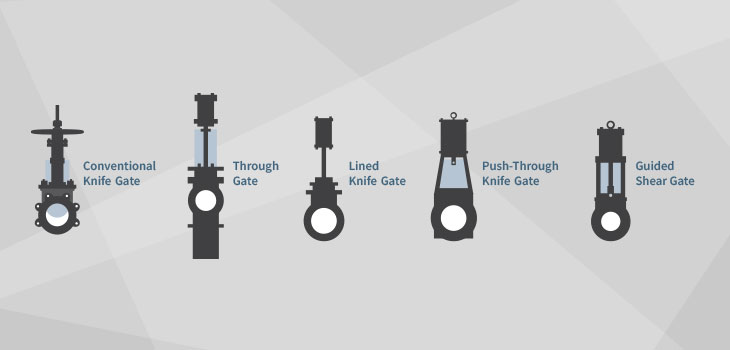

Types of Knife Gate Valves

There are several versions of the Knife Gate Valve design. It is important to note that some Knife Gate Valves operate in harsh severe service applications, where as others simply cannot hold up in these conditions – they simply weren’t manufactured to do

What is a Knife Gate Valve?

Knife Gate Valves (KGVs) were first created for the Swedish Pulp and Paper industry in the 1920s. The market demanded an inexpensive valve for pulp stock applications, and the revolutionary knife gate valve design was born. Since then, knife gate valves have traveled

Valve Standards

For consistency amongst manufacturers, valves are designed to meet established standards. These standards are set for valve performance, design, materials, and functionality. This article aims to cover the organizations responsible for establishing standards in valve manufacturing, along with common valve ratings and testing

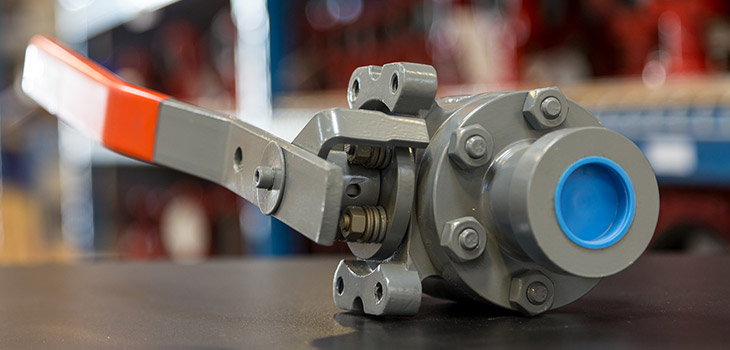

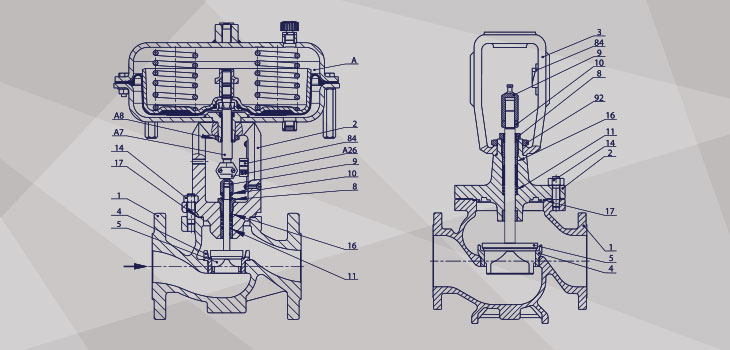

Valve Parts

Valves come in all sorts of shapes and sizes. This is also true with the parts that make up these valves. These components can be sorted into 4 main categories, with two of them being subcategories. Non-Pressure Containing Parts Pressure Containing Parts Valve

Valve Basics

What is a Valve? A valve is a device that regulates the flow of gases, liquids, or loose materials through an aperture, such as a pipe, by opening, closing, or obstructing a port or passageway. Valves perform different functions to suit their applications.