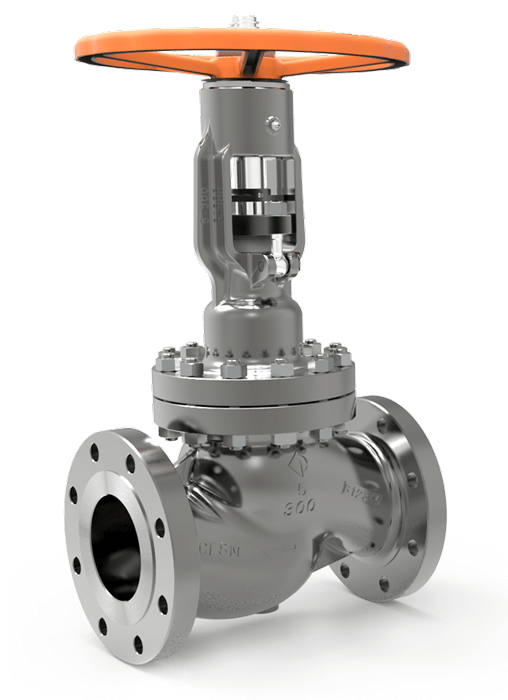

Globe Valves

Globe valves rely upon a flat or tapered plug moving perpendicular to the pipe. They can be used for isolation or throttling flow and are well suited for controlling flow.

Globe valves are very simple in operation. Rotating the stem raises the plug off the seat, allowing line media to flow. Lowering the plug onto the seat throttles or shuts off the valve.

Globe valves are best chosen for throttling applications

Advantages

Widely employed to stop, start and throttle flow.

- Valve bonnets can be adapted to accommodate varying application temperatures.

- The turn-down ratio and repeatability of globe valves will be better than the equivalent ball or butterfly valve.

- The ability to select different plug and seat configurations allows tailoring valve selection to meet the desired flow curve.

Disadvantages

Some service conditions that preclude use of globe valves include:

- Pigging — a globe valve will not be able to be cleaned using pigs.

- Abrasion — due to the multiple changes in flow direction of the flow path through a globe valve, abrasives in the line media will quickly destroy a globe valve.

- Flow capacity (Pressure drop) — also due to the multiple changes in flow direction, pressure drop across a globe valve will be much higher than the equivalent size butterfly, gate, or ball valve.