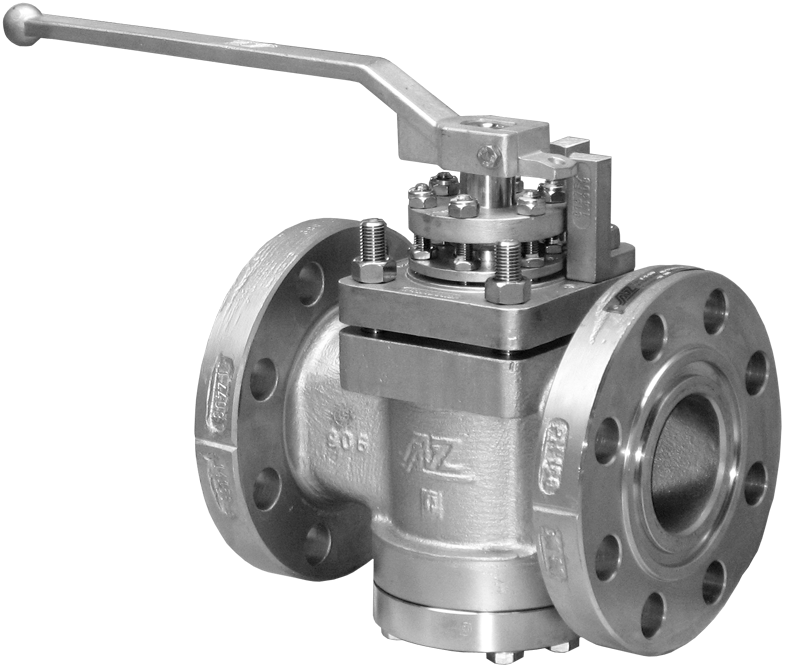

Plug Valves

Composed of a cylindrical tapered plug mating with the top entry body, plug valves are fast acting quarter or 180 ° turn valves.

Depending on the design, plug valves can offer full bore (100% flow capacity, very low pressure drop) although most are reduced bore (~70% flow capacity, low pressure drop) options. Generally un-lubricated plug valves are used in Classes 150 (PN 20) and 300 (PN 50), while lubricated plug valves ca be used in higher ASME Classes.

Plug valves are either lubricated or non-lubricated sleeve-lined. Non- lubricated valves use Teflon or other plastic sleeves, which have self lubricating properties to provide tight shut-off or modulating control. With lubricated valves, the lubricant must be suitable for the system, especially when dealing with food & beverage or water applications.

Plug valves have two big advantages

In addition, they are inherently useful in dirty, high solids applications and can also be used in corrosive applications with their fully PFA Teflon lined versions.

One limiting application is high temperature; plug valves are typically used below 260 °C / 500 °F.