VALVTECHNOLOGIES

ValvTechnologies Product Focus

Zero-Leakage Ball Valves

ValvTechnologies is a leader in the manufacture of severe service, zero-leakage solutions.

VALVTECHNOLOGIES

Key features & Benefits

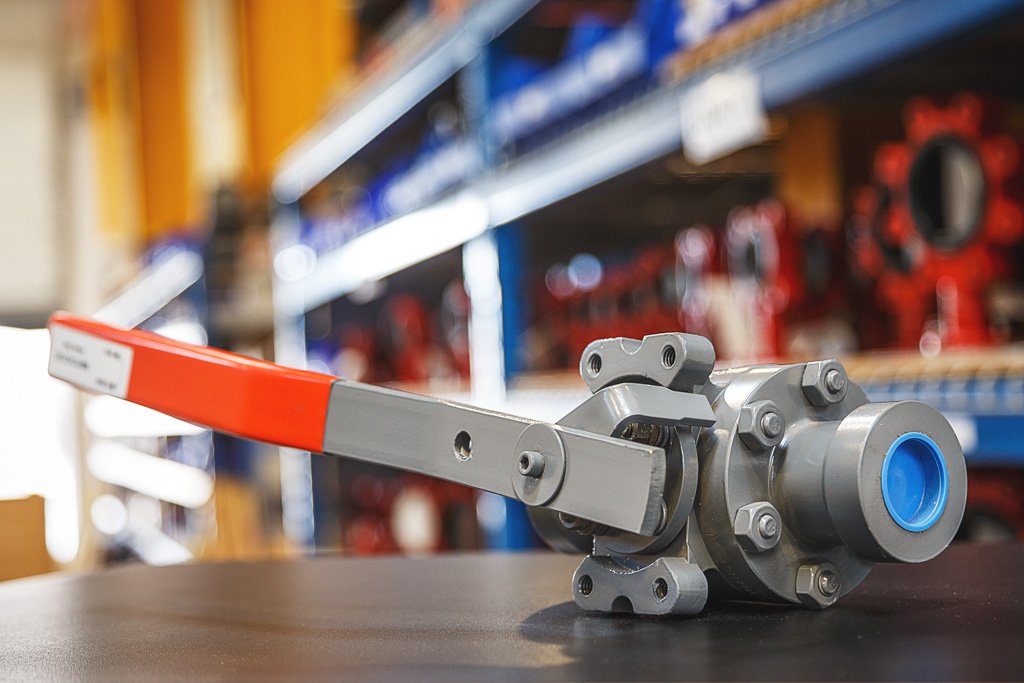

V1-1 Severe Service Metal Seated Ball Valve

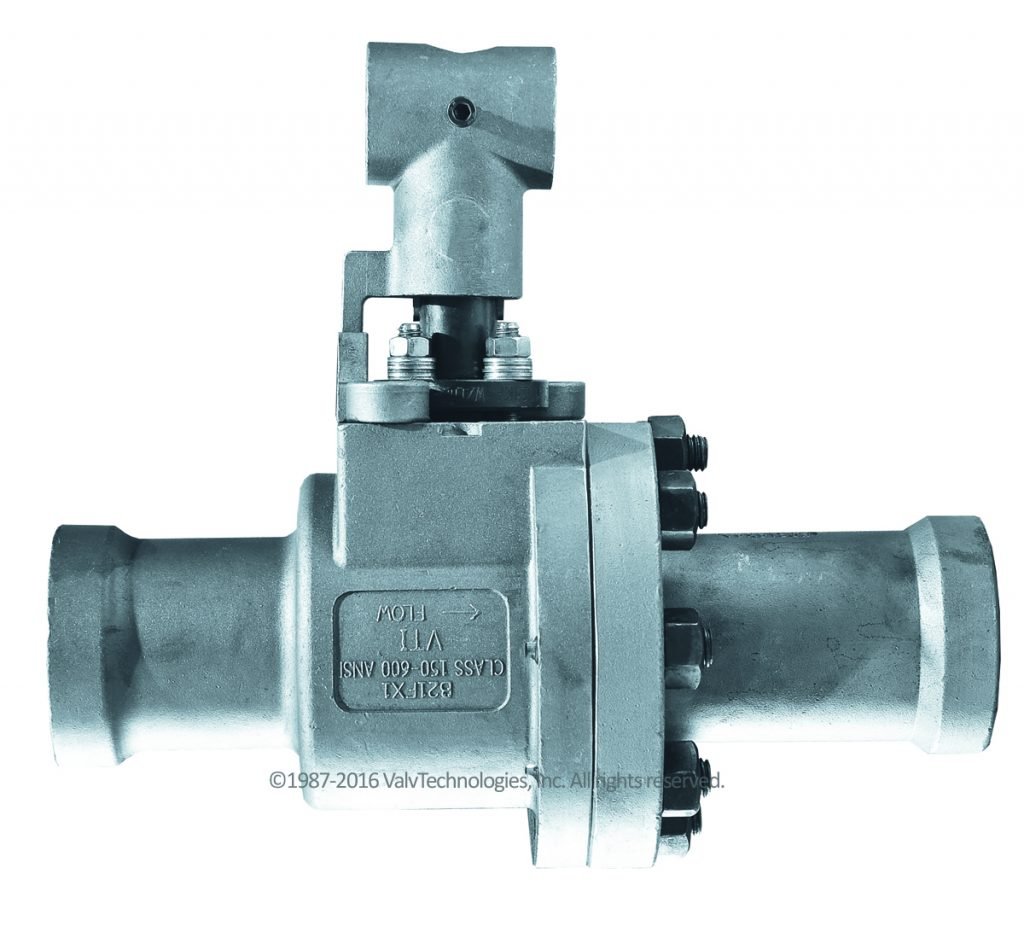

In combination with the HVOF coating, the integral metal seat used in the V1 Series is resistant to wear and tear caused by abrasive materials and ferrous oxides. This helps in reducing downtime and overall cost of ownership.

Body Seal RingThe V1 series uses precision machining, a HVOF ceramet coating process, and mate lapping along with their innovative seal-ring technology that ensures sealing under all operating conditions, up to 1400 degrees Fahrenheit. Valves over 3” containing a second Grafoil seal to guarantee reliability. The V1 series is able to achieve uninterrupted operation in the most severe conditions.

Coating ProcessUsing the ceramet coating process, utilizing Tungsten or Chromium Carbide, ValvTechnologies is able to create a sealing surface that can reach a hardness of 68 – 72 Rc. Ensuring operations in even the most severe conditions can go uninterrupted.

Live Loaded Gland AreaValvTechnologies V1 Series has perfected the use of Bellville springs to provide consistent and constant load pressure in the gland area. The V1 series uses these Grafoil rings to mitigate against the pressures of thermal shocks to prevent usage leaks in severe service applications.

Blow-Out Proof StemThe design of the V1 series features a single-piece, hard-faced, blow-out proof stem that totally eliminates the chances of a blow-out in the gland area. With no options for the media to escape, this blow-out proof stem is vital in ensuring zero-leakage valves.