What is a Valve?

A valve is a device that regulates the flow of gases, liquids, or loose materials through an aperture, such as a pipe, by opening, closing, or obstructing a port or passageway.

Valves perform different functions to suit their applications. These functions are to isolate, control, and check. Depending on what function is needed, there are plenty of different valve designs to select from. These designs vary based on their intended function and physical attributes.

This article will cover the basics of valve function, types, and the media they regulate.

Valve Functions

Isolation Valves: An Isolation Valve (also referred to as block valves or shut-off valves) intends to stop the flow of line media in a piping system. Isolation is achieved by fully opening or fully closing the valve.

Isolation valves are the most common type of valve for industrial applications. One common issue for isolation valve users is finding a valve that can provide true 100% zero-leakage isolation.

Common Isolation Valves include Ball Valves, Plug Valves, Butterfly Valves, and Gate Valves.

Control Valves: Control Valves modulate the flow of line media, typically to maintain a desired variable in the piping system. These valves are used to throttle the flow of line media. This control of the line media is used to maintain a desired variable in the piping system, such as pressure, flowrate, temperature, pH or other operational conditions.

Common Control Valves include Plug Valves, Butterfly Valves, Globe Valves, and Ball Valves.

Check Valves: Check Valves are used to restrict flow to only one direction of the piping system and prevent backflow. The valves open from line media pushing the valve open and close when the flow rate is insufficient to keep the valve open. That means check valves operate automatically and generally require no external source of power.

Common Check Valves: Swing Valves, Single-Flapper Wafer Valves, Double-Flapper Wafer Valves, Lift Valves, and Duckbill Valves.

Types of Valves

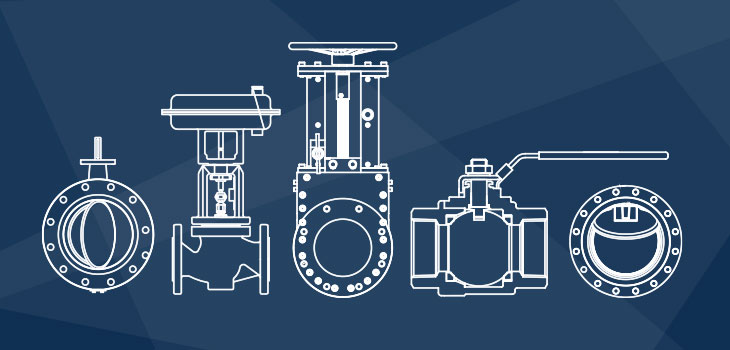

The Six Most Common Valve Designs:

- Gate Valves are relatively simple isolation valves, the most common of which are wedge gates. They involve a gate that can be opened or closed to isolate the media and stop the flow. Gate valves are relatively simple to repair and are generally larger and heavier than other types of valves. They are not suitable for throttling services.

- Globe Valves are designed for both control and isolation but can also be used only for isolation. Globe Valves force line media through a complex path designed to slow the media down as it passes through the port. These are easy to repair and can often be repaired without removal from the piping system. They are used for throttling services.

- Ball Valves are common valves that are found in a myriad of places. Depending on the design, Ball Valves can be used for isolation or control. The Ball Valve receives its name from its pivoting ball, which either seals off flow or allows the media to pass through.

- Check Valves are also called non-return, swing, piston, ball, double-disc, and silent checks. Depending on the severity of the application, the more severe of a design will need to be chosen. In general, Check Valves allow flow in one direction, with most of them operating without any external control or energy source.

- Butterfly Valves are a very common isolation valve. They can also perform control functions but lack precise control. The three main Butterfly Valve designs are rubber seated, double offset, and triple offset. Typically, Butterfly Valves are smaller and lighter than the equivalent Gate, Globe or Ball Valves.

- Plug Valves are the oldest valve design. Plug Valves can be used to block or regulate flow. This is done by a center plug in the valve, that can rotate to isolate or allow flow. Plug Valves are no longer as common as they once were, as they are being replaced by newer designs.

Types of Media

Depending on the design, valves can handle an array of line media. There are typically three categories of solutions that are found in piping systems.

- Gases, such as natural gas, steam, or compressed air

- Liquids such as water, beer, industrial chemicals

- Loose material such as fly ash, powdered coal, sand, dry cement

- Or mixtures of any combination of all three types, such as mining slurries, raw petroleum products, municipal waste

Conclusion

This concludes the introduction to valves. We have learned what a valve is, their functions, and common designs of valves. In whole, valves regulate line media through three main functions. Those functions are to isolate, control, and check. Designs vary depending on what functions they perform and their physical characteristics. Read more in Valve History.