In industrial piping systems, preventing reverse flow is critical to protecting equipment and maintaining safe operations. That is where check valves—also known as non-return valves play a vital role. These valves allow flow in one direction while automatically preventing backflow. Poor valve selection can lead to catastrophic failures. For industrial operations, these risks can translate into costly downtime.

This article provides a simplified overview of check valves, their types, and applications. For more technical details and full guidelines, you can download the complete article here.

What is a Check Valve?

A check valve is a self-actuated device designed to allow flow in one direction and block it in the other. Unlike control or isolation valves, check valves require no external actuation. They rely solely on internal mechanisms such as discs, flappers, balls, or pistons that respond to system flow and pressure.

When the flow moves forward, the internal element is pushed open. As velocity slows or reverses, the element closes against the seat, preventing reverse flow. In theory, one universal design might seem sufficient, but in practice, no single valve suits every application.

Learn more about valve fundamentals in our Valve Basics article.

How Does a Check Valve Work?

The performance of a check valve depends heavily on the conditions of the system where it is installed. Several key factors influence its behavior:

- Flow velocity – A minimum velocity is required to keep the valve fully open. If undersized or oversized, the valve disc may flutter or remain partially closed.

- Pump type and operating curves – Rapid pump starts and stops impact closure speed.

- System layout – Orientation, pipe size, and connection method affect valve operation.

- Media – Gas, liquid, or slurry flows each require different valve features.

Improperly sized or selected check valves often fail to remain fully open under normal conditions. This leads to turbulence, pressure drops, and reduced service life. Oversizing not only increases purchase costs but also accelerates wear. By carefully matching the valve design and size to system parameters, reliability and longevity are greatly improved.

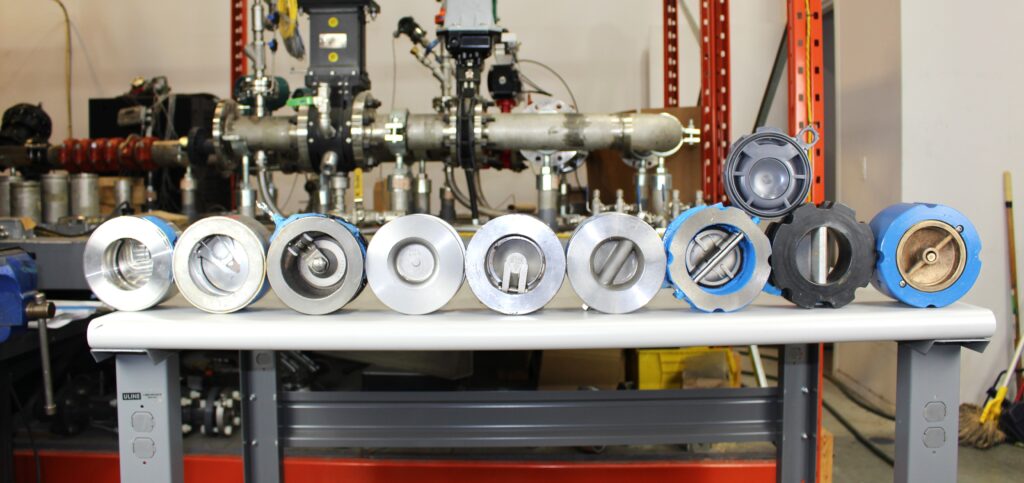

Check Valve Types and Their Applications

There are several check valve types, each suited to different conditions. Below are the most widely used, along with their features, benefits, and limitations. For more practical solutions beyond these general categories, explore our Check Valves product page for more details on available options.

Swing Check Valves

The swing check has historically been the most common valve in pipelines larger than two inches. It uses a hinged flapper that swings open with forward flow and closes by gravity and reverse pressure.

The majority of documented failures include improper seating, sticking open, restricted motion of flow, and loose or damaged parts (1). They are also prone to water hammer because closure is delayed until reverse flow occurs. Their large size and weight add cost and complexity.

For most modern applications, swing checks are considered less efficient and should be applied with caution. Some designs, such as the Chaoda Swing Check Valve, demonstrate reliable backflow prevention when properly sized and applied.

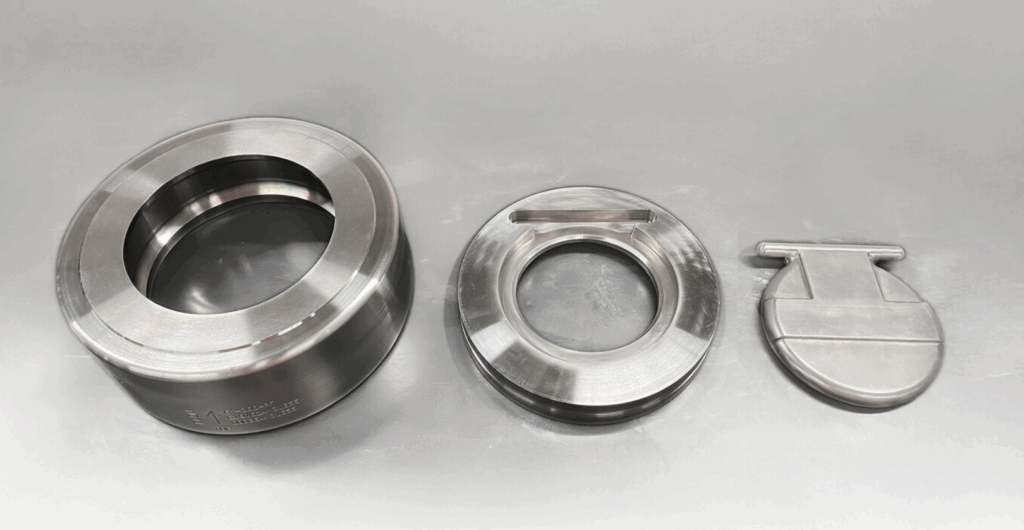

Wafer (Single-Flapper) Check Valves

Wafer check valves are compact, spring-assisted designs that conform to API 594 or API 6D short patterns. Their single flapper is sized to fully open at normal system velocities, reducing the risk of disc flutter.

High-quality wafer checks offer superior isolation performance, with options for elastomer, polymer, or metal seating. Their spring-assisted closure also minimizes water hammer. For many applications, properly sized wafer checks represent one of the most effective choices among check valve types.

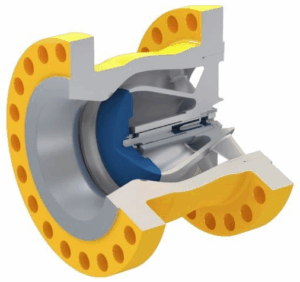

Dual Disc (Double-Flapper) Check Valves

Dual disc valves split the flapper into two lighter segments, reducing mass and allowing use in low-pressure or low-velocity systems. They are cost-effective and widely available.

However, their service life is often limited in systems with two-phase flows, suspended solids, or improper sizing. Premature wear and failures are common under demanding conditions, making them less reliable than single-flapper wafer checks (1).

Ball Check Valves

The ball checks are most common in small-diameter lines (under two inches). They use a free-floating ball that is pushed open by flow and reseats when flow reverses. Specialty designs exist for chemical and slurry service, with sizes reaching up to 36 inches.

The ball checks have lower flow capacity (Cv) and a limited application range. They are not typically used in critical or large-scale industrial systems.

Tilting Disc Check Valves

Tilting disc valves position the hinge point closer to the disc’s center, reducing travel distance and closure time. This makes them better at preventing slam compared to swing checks.

They are often selected for applications such as pulp stock and boiler feedwater. Although more reliable than swing checks, they are still less efficient than properly sized wafer or silent check designs in many systems.

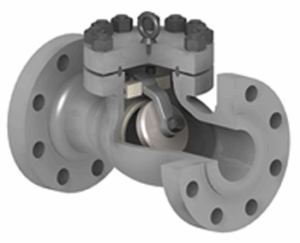

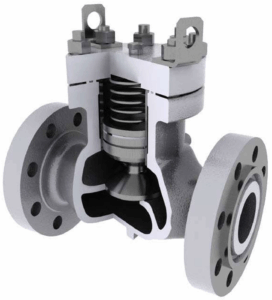

Piston Check Valves

These small valves, usually up to two inches, use a piston that lifts with flow and reseats by gravity or spring tension. They are generally threaded or welded into piping.

While effective in certain situations, piston checks can stick in open or closed positions, particularly without regular inspection(1). They are suitable for limited applications but are not considered a universal solution.

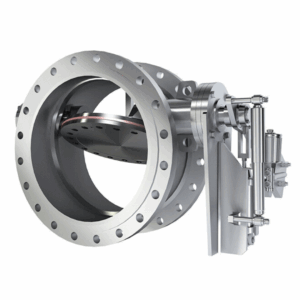

Combined Function Check Valves

These multi-purpose valves integrate check, isolation, and control functions into one unit. By extending the shaft outside the valve body, actuators can be added for manual or automated control.

They are often used in large-diameter pump discharge systems, where water hammer is a risk. Their ability to combine functions and dampen closure speed makes them valuable in critical service, but they are complex and specialized. For example, Adams combined function valves are widely recognized in the industry for their reliability in large-diameter water systems and pump discharge applications.

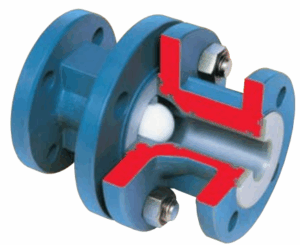

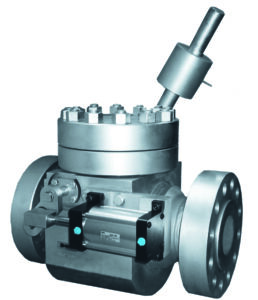

Y-Pattern Stop Check Valves

A traditional design often found in steam boiler service, Y-pattern stop checks combine free closing action with the ability to be manually locked shut. They are typically hardfaced for durability. Though considered old-fashioned, they remain in use in conservative industries such as power generation.

Centre-Guided Spring (Silent) Check Valves

Also called nozzle or silent checks, these valves use a spring-assisted disc in a narrow body or globe-style body. They are designed for pulsing or highly variable flows and close quickly to prevent water hammer.

However, improper sizing or installation in systems with two-phase flows or solids can lead to “stuck open” failures(1). Careful engineering is required to apply these valves effectively.

Slurry Check Valves

Designed for highly abrasive services, slurry check valves use hardened materials such as carbide-coated flappers and polyurethane seats. They have been proven in mineral concentrate pipelines for decades.

Their durability makes them indispensable in mining and metallurgical processes, where conventional valves fail prematurely under high-solids conditions.

Each valve type has unique features and considerations. For detailed specifications and technical discussion, you can download the full article here.

Applications Across Industries

Check valves are applied across nearly every sector that involves fluid handling. A few common examples include:

- Water and Wastewater – Preventing pump backflow in treatment plants.

- Mining and Slurries – Handling abrasive concentrate pipelines.

- Oil and Gas – Protecting compressors, refineries, and pipelines.

- Power Generation – Managing boiler feedwater and steam flows.

Each industry requires tailored valve choices, with slurry checks for high solids, silent checks for pulsing flows, and wafer checks for general service.

Choosing the Right Check Valve

Proper valve selection depends on more than matching line size. Considerations include:

- Flow velocity and required Cv

- Media type (liquid, gas, slurry)

- Operating pressure and temperature

- Pipe orientation and layout

- Maintenance requirements

The correct valve type lowers the total cost of ownership by extending service life and reducing unplanned outages. In severe conditions, specialty designs such as nozzle checks or slurry checks may be essential. For even greater reliability in demanding applications, DSS Severe Service Check Valves are engineered to withstand extreme pressures, pulsing flows, and abrasive media.

Learn more about our expertise in Severe Service Valves.

Common Issues & Maintenance Tips

Even high-quality valves can underperform if misapplied. Common issues include:

- Water hammer from delayed closure.

- Stuck open or closed conditions due to debris or poor sizing.

- Premature wear caused by oversizing or wrong materials.

Regular inspection, accurate sizing, and working with experienced suppliers can help avoid these issues. In many cases, failures are not due to poor manufacturing but rather to incorrect application.

Conclusion

There is no single “perfect” valve that works in every situation. Each style has strengths and limitations. By understanding what is a check valve, how it works, and the differences among the main check valve types, operators and engineers can make informed decisions that improve safety, reliability, and cost efficiency.

At CGIS, we have decades of experience applying check valves in some of the world’s most demanding environments. Whether your application is water treatment, mining, or power generation, our team can help you identify the most effective solution.

Contact us today for a free consultation with our experts to find the right check valve for your application.

(1) K.L. McElhaney, “An Analysis of Nuclear Check Valve Performance by Valve Type”, Valve Magazine, 1997, Volume 9, No. 3