Knife Gate Valves (KGVs) were first created for the Swedish Pulp and Paper industry in the 1920s. The market demanded an inexpensive valve for pulp stock applications, and the revolutionary knife gate valve design was born.

Since then, knife gate valves have traveled back and forth across the globe undergoing several alterations; the Push-Through Knife Gate was developed in the United States while the Guided Shear Gate was developed in Switzerland.

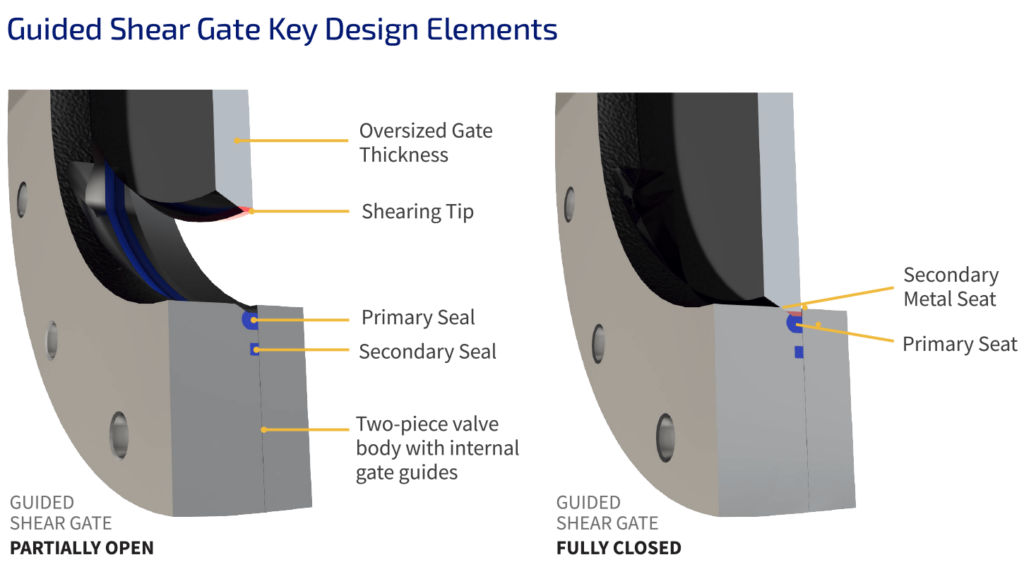

While we’ve accepted the term “knife gate” as a generic name for each version of this valve, you may be surprised to find out that the only the Guided-Shear Gate and its higher-caliber adaptation, the Severe Service Knife Gate Valve (SSKGV) can truly “cut” through media like a knife.

All the older iterations of the valve are still on the market today — meaning you will run into Through-Gates, Lined Gates, Push-Through Gates or Guided Shear Gate designs in industrial processing plants around the world. The technology has advanced significantly, but many operations have failed to upgrade.

Imagine still watching a black and white TV in today’s day and age, you could theoretically buy one, but why would you? It still might work – but not very well. While these designs may still offer shut off from flow, their ability to isolate can vary dramatically, depending on the application. Specifications for allowable leakage vary (think differential pressure, media, time, etc.)

For example, a Push-Through Knife Gate in a mining facility in Alaska will most likely see freezing conditions, causing the water outside of the pipeline (from discharge) to freeze and expand, in turn breaking discharge ports and pressure retaining boundary resulting in potential valve failure.

In this instance, a Guided Shear Gate Valve or better yet, a Severe Service Knife Gate Valve would have eliminated discharge.

Overall Cost of Ownership

We’re aware of the high costs of replacing valves, especially those already in operation. That’s why we’ve put together this table to show that long term investments in valves that do not leak, will lower your overall cost of ownership by reducing downtime from maintenance and the total number of valve replacements or repairs required during the lifespan of the valve.

The example below is a simplified version of a real example we’ve seen in the past at an iron concentrate mine on a concentrate dewatering filter where the valves cycle an average of 70 times a day.

| Valve Type | Valve Cost | Average Valve Life | Valve Replacement Downtime Cost (4hrs) | Total Cost Over Two Year Period |

|---|---|---|---|---|

| Push-Through Knife Gate Valve | $5,000 | 2 months (1/6 year) | $23,000 | Valve cost: $60,000 Downtime: $276,000 TOTAL: $316,000 |

| DSS Severe Service Knife Gate Valve | $8,700 | 2 years | N/A | Valve cost: $8,700 Downtime: $0 TOTAL: $8,700 |