In the valve industry, it’s common to think that one butterfly valve can work just as well as another. But in reality, design differences can lead to major performance gaps, especially when it comes to shutoff, service life, and reliability in tough operating conditions.

This becomes clear in critical service environments, where conventional butterfly valves often can’t meet the demands for tight shutoff, long life, or resistance to harsh media.

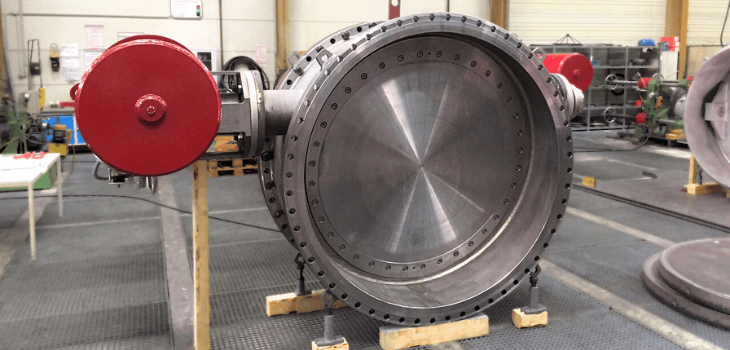

Triple offset butterfly valves were created to solve these exact problems. By removing friction during seating and sealing more tightly, this design has set a new standard in valve performance. One of the best known examples of this innovation is a valve from ADAMS Valve that applies these principles in the field.

For a basic introduction to valve principles, see our Valve Basics resource.

Butterfly Valves: Basic Function and Principles

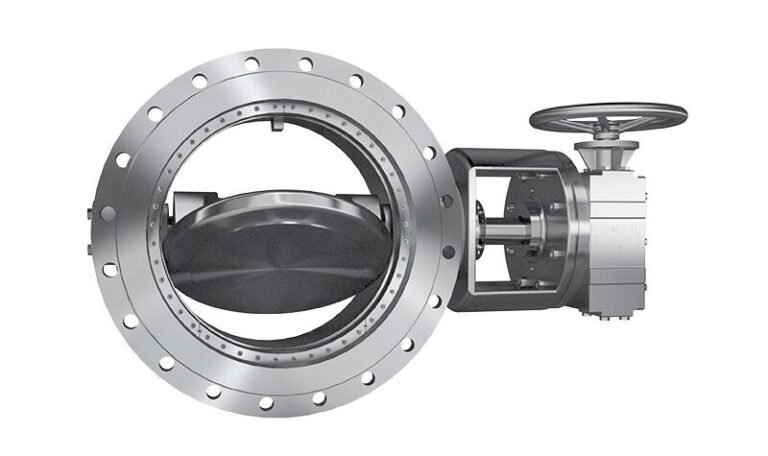

A butterfly valve is a quarter-turn rotary valve that uses a disc mounted on a rotating shaft to regulate flow. When the valve is fully open, the disc turns parallel to the flow, allowing fluid to pass. When closed, the disc rotates perpendicular to the flow, sealing the line.

These valves are popular because they are compact, simple to operate, and cost-effective. But how the disc seals against the seat is what determines how well they perform.

Most butterfly valves operate using one of two seating principles:

- Position Seating: The disc rotates into a fixed position against the seat. While common, this method relies heavily on actuator limit stops, making it more prone to wear and leakage over time.

- Torque Seating: The actuator applies torque to the disc, pressing it into the seat with precision each cycle. This method is more reliable, reduces leakage, and minimizes friction.

This seating principle is what makes Triple Offset butterfly valves different from conventional designs.

Types of Butterfly Valves

Butterfly valves are grouped into five main types: damper, resilient seat (concentric), single offset, double offset (high performance), and triple offset.

Each type performs differently under pressure, temperature, and media conditions. Learn more about the basics of butterfly valves in Butterfly Valves 101.

Triple offset valves stand out because they are designed to handle tough service environments where the others struggle.

The Evolution of Torque-Seated Triple Offset Butterfly Valves

The triple offset rotary tight shutoff valve was patented by Karl Adams in 1960 to solve leakage problems found in older valve designs used in district heating systems. His innovation focused on three principles that remain the foundation of triple offset technology today:

- Zero friction: The disc lifts away from the seat without rubbing, removing wear caused by sliding contact.

- Zero leakage: The angled sealing surface and torque-seated design provide a tight, bubble free seal.

- Zero maintenance: With minimal wear on the seat and disc, the valve can run longer without frequent servicing.

These design principles make the triple offset valve a trusted option in critical systems. The ADAMS Valve was developed using these principles and has since become a well-known example of this technology.

Material and Construction Advantages

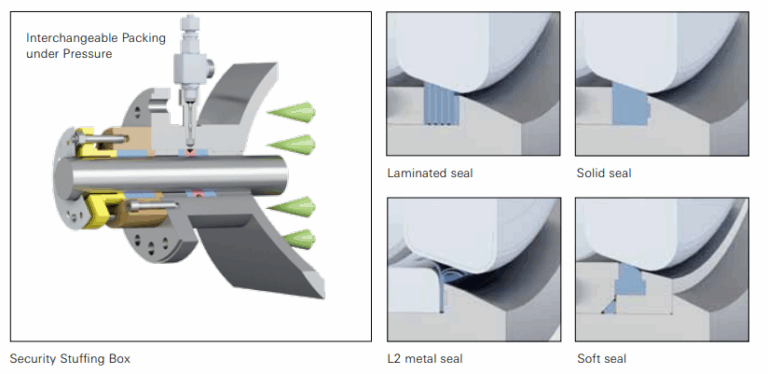

A key feature of the ADAMS design is its body-mounted laminated stainless steel and graphite seat ring. This approach solves several common problems found in conventional valves:

- The seat is shielded from direct flow, reducing erosion caused by abrasive media.

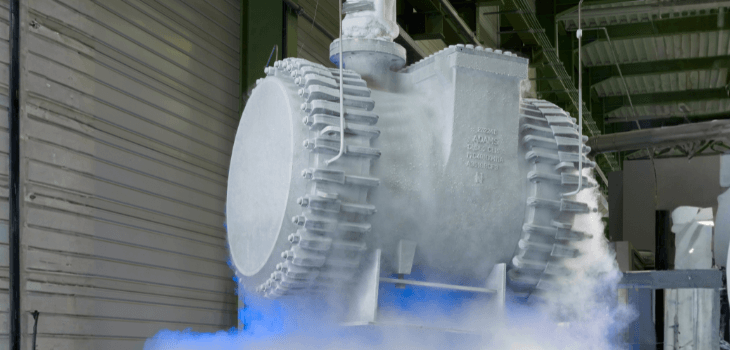

- The laminated stainless steel and graphite provide strength and lubricity, allowing the seal to stay tight even under harsh conditions like steam, slurry, or cryogenic service.

- Unlike soft seat materials, which can tear or deform, this configuration resists damage and delivers longer service life.

- When maintenance is required, the seat can be replaced in the field, without removing the entire valve.

Applications Across Industries

Triple offset butterfly valves provide tight shutoff, long cycle life, and minimal maintenance, even in harsh operating environments. Their design allows them to meet and exceed ASME Class VI leakage standards.

Common applications include:

- LNG and Cryogenic Applications – No trapped cavities, zero leakage performance.

- Power and Energy – High-pressure, high-temperature steam systems.

- Water and Wastewater – Long service life and low maintenance.

- Pulp and Paper – Handles abrasive, scaling media effectively.

- Chemical and Mining – Resistant to corrosive or erosive conditions.

ADAMS Valve vs. Regular Butterfly Valves

Shaft & Drive Components

| Feature | ADAMS Valve | Conventional Butterfly Valve |

|---|---|---|

| Shaft Diameter | Large, robust | Slender |

| Connection | Precision keys, no backlash | Wedge/taper pins |

| Mounting | Precision fit | Slotted, less stable |

Seat Design & Replacement

| Feature | ADAMS Valve | Conventional Butterfly Valve |

|---|---|---|

| Seat Location | In body, protected from flow | In disc, exposed |

| Material | Laminated stainless steel/graphite | Elastomer/PTFE |

| Replacement | Simple, field replaceable | Factory service often required |

Performance & Leak Integrity

| Feature | ADAMS Valve | Conventional Butterfly Valve |

|---|---|---|

| Sealing | Metal-to-metal | Soft seat |

| Leak Class | Zero leakage | Class IV/V typical |

| Reverse Flow | Maintains tight shutoff | Reduced performance |

Maintenance & Service Life

| Feature | ADAMS Valve | Conventional Butterfly Valve |

|---|---|---|

| Life Cycle | High cycle count | Lower, dependent on wear |

| Maintenance | Minimal, fast seat change | Frequent downtime |

| Applications | Severe service ready | General service only |

Why Proper Valve Selection Matters

Choosing the right valve is about more than pressure ratings and line sizes. Picking the wrong valve can lead to leaks, more frequent maintenance, and unplanned downtime. Triple offset valves like ADAMS provide a clear advantage in tough operating conditions:

- Zero leakage sealing performance

- Long service life with fewer maintenance interventions

- Lower overall cost of ownership

By understanding how different butterfly valve designs work, engineers and procurement teams can make smarter decisions that reduce risk and improve system reliability.

Conclusion

Not all butterfly valves are built the same. Triple offset butterfly valves have changed what industries can expect from a rotary valve, offering frictionless operation, tight sealing, and extended life in applications where reliability matters most.

Talk to our specialists about ADAMS Valves and other butterfly valve solutions for your application.

Contact us for a free consultation today.

References:

Niebergall, K. Is a Butterfly Valve Just a Butterfly Valve? CGIS White Paper, 2017.

ASME B16.104 Valve Seat Leakage Standards.

API 598 Valve Inspection and Testing Standard.