Control valves are critical elements that regulate flow, pressure, temperature, and level within a process. Without the right valve, even the most advanced plant design can suffer from inefficiency, safety risks, or costly downtime.

Choosing and applying valves correctly is one of the most important decisions in plant design and operation. In this article, we’ll look at what control valves are, how they work, the different types available, and where they are used across industries.

For more technical detail and case studies, download the full white paper:

Selecting the Correct Control Valve.

What is a Control Valve?

A control valve is a device that regulates the flow of fluids, liquids, gases, or steam through a system. By adjusting the size of the flow passage, it maintains desired process conditions such as flow rate, temperature, pressure, and level.

In process control, valves are considered the “final control element.” They take signals from a controller and physically adjust the flow, ensuring that upstream fluctuations don’t compromise downstream stability. In other words, they are the hands of the control system, acting on instructions to keep processes running smoothly.

Explore our Control Valves product page to see solutions designed for both general and severe service conditions.

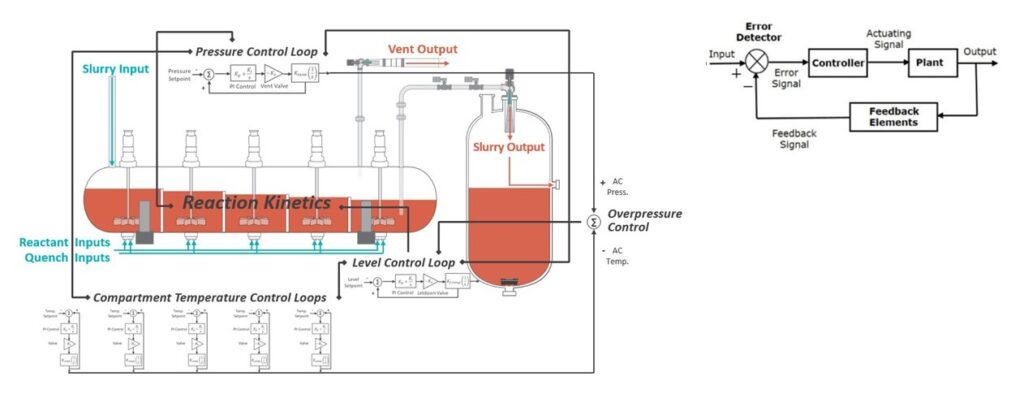

How Do Control Valves Work?

At the heart of a control system is the control loop. A sensor detects process conditions, such as pressure or flow. The controller then compares this to the desired setpoint and sends a signal to the valve actuator. The actuator adjusts the valve’s position, either opening or closing it, until the process variable reaches the setpoint.

By modulating flow in real time, control valves prevent process upsets, protect equipment, and help maintain safety and efficiency.

Types of Control Valves

Control valves come in several types, each with strengths and limitations. Selecting the right one depends on process requirements. Here are some of the main types:

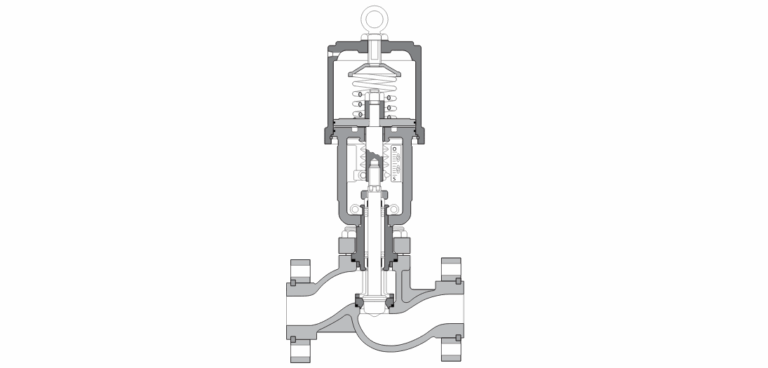

Globe Valves

Globe valves are one of the most widely used designs, valued for precise throttling and control. They can be applied in both general service, fit-for-purpose, and severe service applications when fitted with the right trims. Manufacturers such as Mascot produce globe control valves with a range of trim designs and materials to handle demanding environments.

Key Features:

- Tight shutoff capabilities

- Wide rangeability of control

- Available in small sizes

- Severe service trim options

- Alloy materials for demanding environments

Limitations:

- For the same flow capacity, globe valves introduce a higher pressure drop due to their tortuous flow path — though in some applications, this characteristic is advantageous when a significant pressure reduction is desired

- Larger and heavier than rotary designs of similar capacity

V-Port Ball Valves (Control Ball Valves)

V-port ball valves, also known as control ball valves, use a notched ball or seat to improve throttling performance compared to standard ball valves. They are valued for high flow capacity with good rangeability. Mascot offers segmented ball valves designed for reliable control in both moderate and demanding applications.

Key Features:

- High Cv (flow capacity) relative to valve size

- Lightweight design

- Lower cost than globe valves for similar service sizes

- Simple construction and maintenance

Limitations:

- While advanced segmented ball valves can manage moderate cavitation, they are generally not recommended for severe cavitation or flashing conditions

- Higher risk of vibration and downstream erosion in high-pressure services

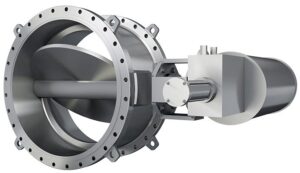

Butterfly Valves

Butterfly valves are compact and cost-effective, often used in large-diameter piping systems where weight and space are considerations. They are common in general service flow control and are well-suited for large-volume flows at relatively low costs. Manufacturers such as Adams produce butterfly control valves used in power generation and other industrial applications.

Key Features:

- Lightweight and compact design

- Cost-effective, especially for large flow volumes

- Easy installation and maintenance

Limitations:

- Not suitable for severe cavitation or flashing applications

- High-performance and triple-offset butterfly valves can handle moderate differential pressures, though they remain less suitable for severe cavitation or flashing

Pressure Relief Valves

Pressure relief valves (PRVs) are safety devices designed to protect equipment and piping from overpressure conditions. When system pressure exceeds a predetermined setpoint, the valve opens automatically to release excess fluid — gas, steam, or liquid — preventing damage or failure. Once the pressure returns to a safe level, the valve reseats to maintain system integrity.

Key Features:

- Automatically relieve excess pressure to protect equipment and personnel

- Available in various designs, including spring-loaded, pilot-operated, and balanced bellows types

- Suitable for gas, steam, and liquid services across industries

- Typically sized and set according to ASME and API pressure safety standards

Limitations:

- Not designed for continuous flow control or throttling applications

- Require periodic inspection and testing to ensure reliable reseating and performance

Severe Service Control Valves (SSCVs)

Severe Service Control Valves are built for extreme conditions where standard designs fail quickly. They are critical in processes involving cavitation, flashing, high noise, or erosive flows, and are widely applied in power generation, pulp and paper, oil and gas, and mining. Companies like Nova Hydromet manufacture Severe Service Control Valves specifically for these demanding environments.

Key Features:

- Multi-stage trims to control pressure drops

- Hardened alloys and specialized materials

- Designs that manage noise, vibration, and erosion

- Used in power, pulp & paper, oil & gas, and mining

Limitations:

- Higher initial cost compared to general service valves

- May require more space or maintenance planning due to complex trims

Applications Across Industries

Control valves are found across nearly every industry, including:

- Power Generation: Boiler feedwater and steam control often require multi-stage trims to prevent cavitation

- Pulp & Paper: Black liquor and wash water combine flashing, cavitation, and erosion, making them among the toughest services

- Oil & Gas: Separator feeds, flare systems, and hydrocarbon lines often involve multiphase flows and high velocities

- Mining & Hydrometallurgy: Slurries and corrosive leaching fluids demand ceramic trims or erosion-resistant alloys

- Chemicals & Petrochemicals: High-temperature steam and hydrocarbon mixtures pose cavitation and noise risks

Across these industries, one principle remains: the application dictates the valve. Matching the design to the process avoids costly failures and downtime.

Factors in Control Valve Selection

Valve sizing follows standards such as ISA S75.01 (incompressible flow) and ISA S75.02 (compressible flow), while noise prediction methods are covered in IEC 60534-8. It needs to be mentioned that the correct control valve selection is more than a calculation exercise. It blends science with experience.

Factors that influence selection include:

- Process data: Accurate pressures, temperatures, and fluid properties.

- Application severity: Whether cavitation, flashing, or high noise will occur.

- History: Previous experience with similar processes and fluids.

- Customer requirements: Maintenance preferences and lifecycle expectations.

- Cost of ownership: Balancing CAPEX (upfront cost) with OPEX (long-term reliability and maintenance).

Too often, decisions lean toward the cheapest valve that meets minimum requirements. In reality, upfront savings are often offset by higher operating costs when valves fail under severe conditions.

Common Failures of Control Valves

Even with proper design and installation, control valves face conditions that can lead to failure if not properly addressed. Three of the most common issues are:

- Cavitation: Occurs when vapor bubbles form and collapse inside the valve, causing erosion, vibration, and noise. Over time, cavitation can destroy valve trims and reduce flow capacity.

- Flashing: Happens when fluid turns to vapor inside the valve and remains a vapor downstream, leading to continuous erosion of valve surfaces. Flashing typically produces smooth, polished wear patterns.

- Noise: Generated by high velocities and turbulence, noise is more than an environmental issue — it causes vibration, accelerates trim wear, and can reach unsafe sound levels.

These issues are explored in greater detail, with solutions and case studies, in Part 2: Control Valve Challenges.

Conclusion

Control valves play a central role in process control, from general services like water handling to extreme conditions involving high pressure and erosive fluids. Choosing the right type ensures stable operations, longer valve life, and safer plants.

But valves are not all equal. When processes face cavitation, flashing, or noise, Severe Service Control Valves become critical.

To explore these challenges in detail, see Part 2 of this series: [Control Valve Challenges: Cavitation, Flashing, and Noise Explained]. For technical depth and case studies, download the full report about Selecting the Correct Control Valve.

At CGIS, we provide valve solutions for every industry — from general service to the most severe applications. Contact us today for a free consultation to find the right control valve for your process.