There are several versions of the Knife Gate Valve design. It is important to note that some Knife Gate Valves operate in harsh severe service applications, where as others simply cannot hold up in these conditions – they simply weren’t manufactured to do so.

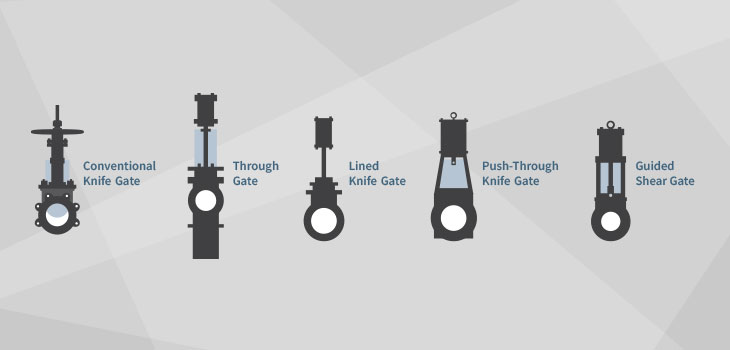

Two categories can be used to better differentiate between Knife Gate Valve designs:

General Purpose/Fit-for-Purpose Knife Gate Valves

- Conventional Knife Gate Valve

- Through Gate Valve

- Lined Knife Gate Valve

- Push-Through Knife Gate Valve

Severe Service Knife Gate Valves:

- Guided Shear Gate Valves (GSGs)

- Severe Service Knife Gate Valves (SSKGVs)

Conventional Knife Gate Valve

The Conventional Knife Gate Valve was created in 1927 in Sweden for the Pulp and Paper industry, when an inexpensive option for pulp stock applications was first required. This valve worked adequately at the time for the specific application but is now seen as outdated.

Created in: 1927

Design: The key design feature with this first iteration are the wedges located typically at 5 and 7 o’clock at the bottom of the port. The wedges push the gate onto the seat when the valve is fully closed.

Capabilities/Where it Works: Low-pressure, unidirectional general-purpose isolation where through leakage is not a concern

Why it Fails: The wedges on the valve are only located on the bottom of the port, allowing for a high amount of through leakage and depending on the size of the valve, especially at the top of the seat.

Industrial Process Industries: Pulp and Paper.

Average Allowable Leakage: 40 cc per inch of diameter per minute.

Other Notes: It is important to note that the average allowable leakage is based on a differential pressure of 40psi. Any lower pressure differential will permit for even more leakage from this type of valve.

Through Gate Valve

The first big change to the conventional knife gate resulted in the Through Gate design (also know as an O-Port), which was able to accommodate higher consistencies of fibre in water, but had issues with through leakage and consistently released large amounts of fugitive emissions.

Created in: 1950s

Design: This iteration removed the wedges used in the Conventional Knife Gate and replaced them with two body seats and top and bottom packing glands. These seats seal the valve when fully closed, and the packing glands seal the valve at all positions. This valve has high through leakage and fugitive emissions.

Capabilities/Where it Works: This valve typically works well in high fibre applications where the fibre can actually become a seat after dewaters.

There has also been a success in mineral processing plants, with high scale because the scale actually helps the valve seal completely.

Why it Fails: This valve should not be used in most industrial applications where high fugitive emissions and through leakage is a concern. The packing glands on this valve add a large amount of weight and size to the valve (and cost), while still allowing for a considerable amount of emissions.

Industrial Process Industries: Pulp and Paper.

Average Allowable Leakage: 40 cc per inch of diameter per minute.

Lined Knife Gate Valve

The Lined Gate was the first design to consider the effects of corrosive applications.

Created in: 1960

Design: The design features a protective corrosion resistant body liner that offered a cheaper, chemical resistant option for corrosive applications.

Capabilities/Where it Works: This valve is a low-cost solution that protects a non-corrosion resistant valve body with a corrosion-resistant liner.

Why it Fails: The manufacturers of this valve only used corrosion-resistant materials on the liner and gate. When the liner fails or when the packing leaks the corrosive material, the body, and eventually the valve, fail. Once the valve starts leaking from the packing (even if just the average allowable leakage) the corrosive materials damage the pressure retaining body of the valve, thus resulting in more leakage and overall valve failure.

Industrial Process Industries: Mining and Mineral Processing, Pulp and Paper.

Average Allowable Leakage: SP-81 or Zero Leakage

Push-Through Knife Gate Valve

The Push-Through design emerged, enabling knife gates to handle high percentage solid slurries in mining.

Created in: 1960

Design: This design uses a sharply edged gate to separate the “sleeves” spreading them apart. Each stroke has a discharge which can increase with every cycle.

Capabilities/Where it Works: Works well in low-pressure, low-cycle, neutral pH slurries.

Why it Fails: On each stroke, the elastomer sleeves loose elasticity, even if just a tiny bit. Eventually, the contact between the two sleeves is insufficient to hold back the internal pressure and the valve starts to free discharge while open.

Industrial Process Industries: Mining and Mineral Processing.

Average Allowable Leakage: Zero-Leakage, but allowable discharge.

Severe Service Knife Gate Valve (SSKGV)

Today, the Severe Service Knife Gate Valve (SSKGV) leads the way with the most technologically advanced design on the market today. The SSKGV completely removes the chance for fugitive emissions, surpasses the rigorous standards for Severe Service defined by the MSS, and provides bi-directional zero leakage from full vacuum to ASME Class 1500/PN 250 pressures (3750 psig/250barg).

Created in: 2017 (Generation V of Guided Shear Gate)

Design: The SSKGV utilizes a Guided Shear Gate Design that consists of three key elements: a mechanically retained axial seat, a shearing gate tip, and internal gate guides. From open to close the gate is guided the entire way removing any option to deflect when solids are encountered. When the material is struck by the shearing tip, it is cut, fractured, and pushed away downstream inside the pipeline (no discharge to atmosphere). These features enable zero leakage, zero emissions, and zero discharge where the gate meets the primary seal. A secondary seal backs up the primary seal for extra peace of mind. Transverse seals coupled with the primary seal prevent fugitive emissions.

Capabilities/Where it Works: Severe Service Knife Gate Valves are designed to handle the harshest of conditions in a variety of industries. That however doesn’t mean they shouldn’t be considered for more general applications as well.

Why it Fails: Though unlikely the primary seal is subject to the erosive and possibly abrasive wear that occurs when the valve is closing against flowing media. However, there are cases where the DSS SSKGV has cycled over 25,000 times with zero leakage.

Industrial Process Industries:

- Mining and Mineral Processing

- Paste Backfill

- Oil & Gas

- Power

- Chemical Processing

- Municipal

- Pulp & Paper

- Steel Manufacturing

- Wastewater

Average Allowable Leakage: Zero Leakage.

Overall Cost of Ownership

We’re aware of the high costs of replacing valves, especially those already in operation. That’s why we’ve put together this table to show that long term investments in valves that do not leak, will lower your overall cost of ownership by reducing downtime from maintenance and the total number of valve replacements or repairs required during the lifespan of the valve.

The example below is a simplified version of a real example we’ve seen in the past at an iron concentrate mine on a concentrate dewatering filter where the valves cycle an average of 70 times a day.

| Valve Type | Valve Cost | Average Valve Life | Valve Replacement Downtime Cost (4hrs) | Total Cost Over Two Year Period |

|---|---|---|---|---|

| Push-Through Knife Gate Valve | $5,000 | 2 months (1/6 year) | $23,000 | Valve cost: $60,000 Downtime: $276,000 TOTAL: $316,000 |

| DSS Severe Service Knife Gate Valve | $8,700 | 2 years | N/A | Valve cost: $8,700 Downtime: $0 TOTAL: $8,700 |