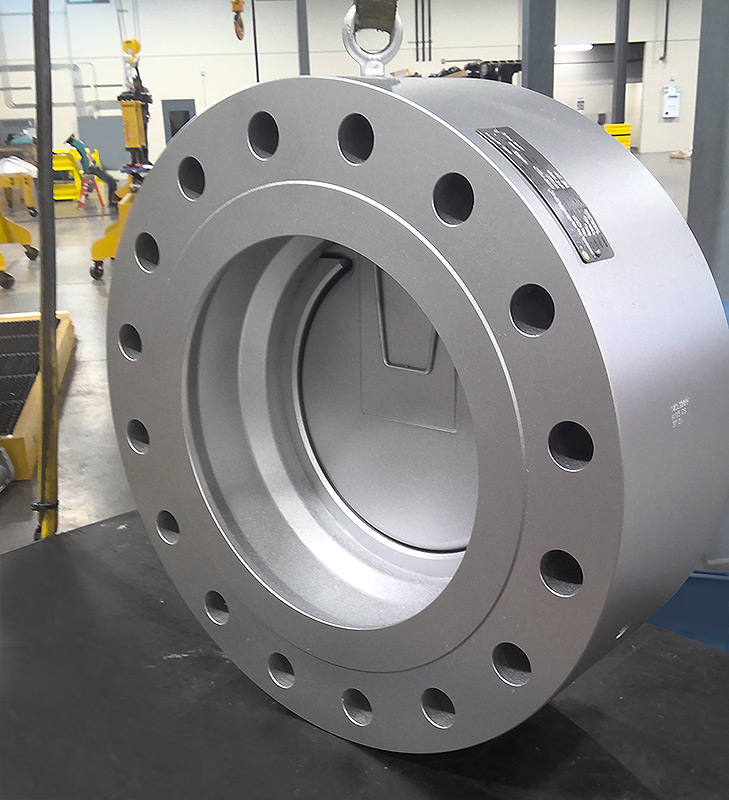

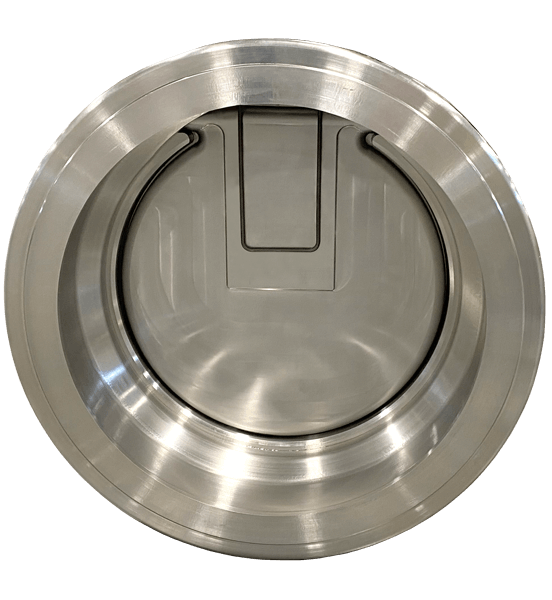

Check Valves

What adds up to make the perfect Check Valve? Cracking at low pressure, remaining completely open during low flows, and lightning fast closing capabilities are all part of the equation.

Best Performance

Another example of where less is more relates to properly selecting the right, often smaller size of check valve for your line. Our 45 years of experience working with Check Valves has taught us that choosing a body size to match the pipe size will often lead to a valve that is not fully open at minimum or even normal flowrates. Unfortunately, this common practice will not lead to the best performance or the lowest cost of ownership. If your Check Valve doesn’t fully open, turbulence and vibration from mechanical movement of the disc will drastically shorten its life.

At CGIS, our commitment to understanding the application, well before a dollar is spent, ensures our customers always get the right valve. When it comes to Check Valves, we combine our industry knowledge and experience with our premium products to minimize your downtime and prevent dangerous consequences from backflow.