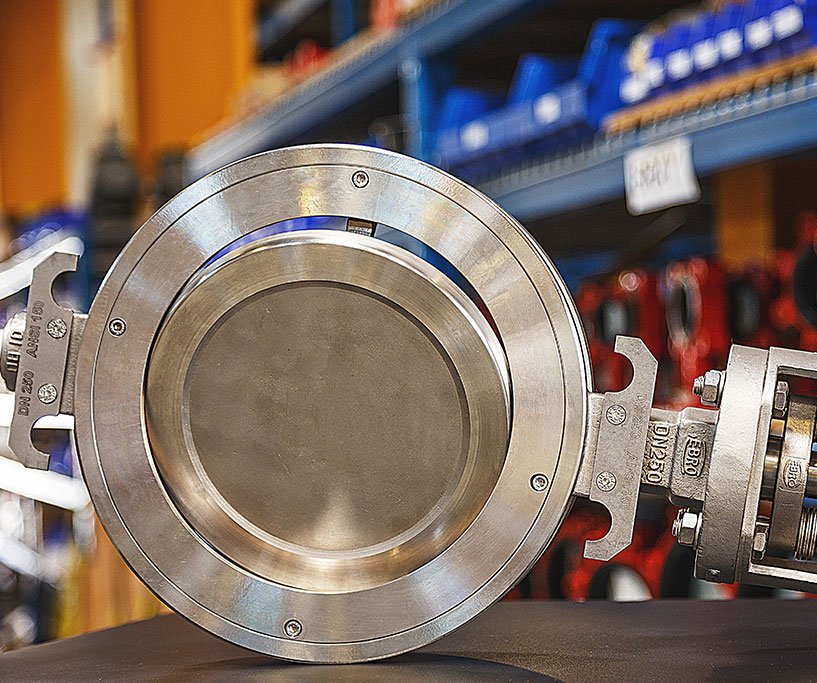

Butterfly Valves

If you are looking for a lightweight and versatile valve that can be used in control and isolation circumstances, there is a good chance that a standard butterfly valve is the best fit for your application.

Instead of using a large ball as the closing mechanism, a butterfly valve can use a disk which enables quick shutoff and drastically reduces the overall footprint of the valve.

Depending on the class, a butterfly valve can range from 3-7 times lighter than ball valves of the same diameter. When installed in a pipeline, they take up a third of the space as a ball valve; ideal for industrial facilities with limited space and difficult to access applications.

Product Focus

Evolving Design

While often simplistic in appearance, the nuances of the butterfly valves design have been evolving in leaps and bounds over the past 30 years. Adams and EBRO are at the forefront of assuring product quality, precision manufacturing, and process integrity. Unlike a control butterfly valve which doesn’t isolate perfectly, these manufacturers started with isolation in mind, then tackled control.

We stand by the fact our butterfly valve manufacturers create the butterfly valves that meet the following credentials:

- Acid Production

- Biogas Feed

- Chlorine Dioxide

- Sulphate Removal

- DIN/PAS 1085

- API

- ASME

- NSF