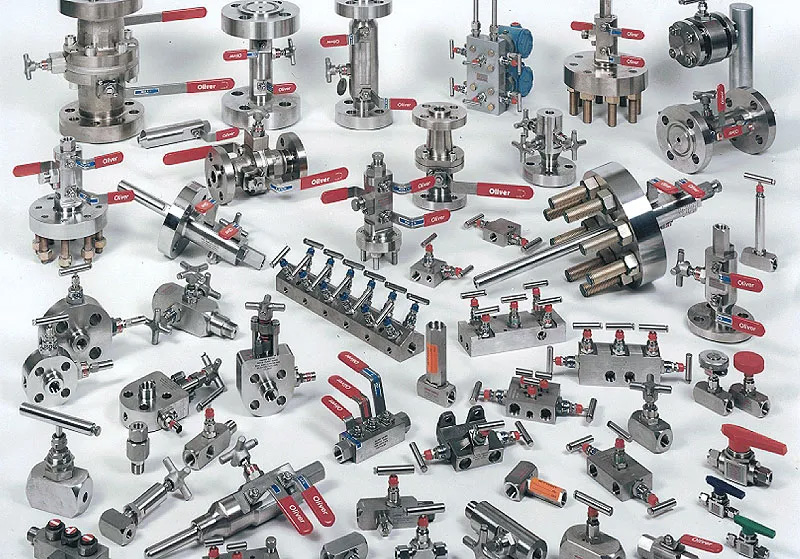

Oliver Valves

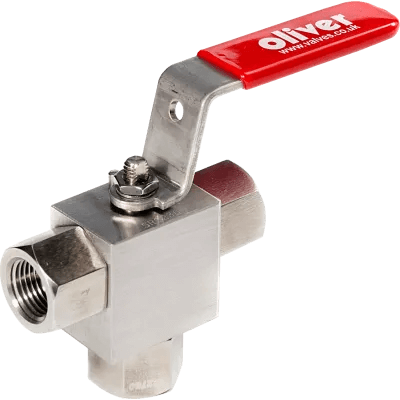

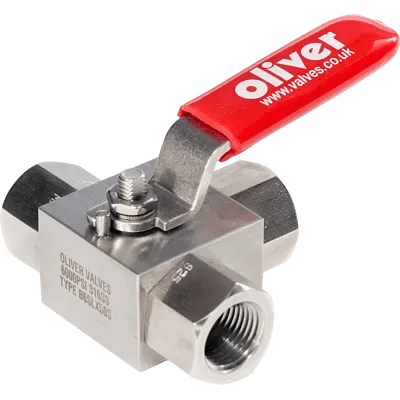

At the heart of Oliver’s offerings are their premium-grade instrumentation valves — including needle valves, gauge valves, hand valves and manifolds — designed for accurate, reliable performance in demanding service conditions.

Engineered to meet stringent standards

Oliver’s valves are engineered to meet stringent standards, including high-pressure, high-temperature and harsh-service requirements, making them ideal for:

- critical instrumentation

- sampling, injection

- venting and isolation applications in oil & gas, chemical, petrochemical, hydrogen, carbon-capture and other industrial sectors

With an extensive stock range, bespoke engineering capabilities, and a reputation for reliability and safety under pressure, Oliver Valves continues to set the standard for instrumentation and DBB valve solutions worldwide.

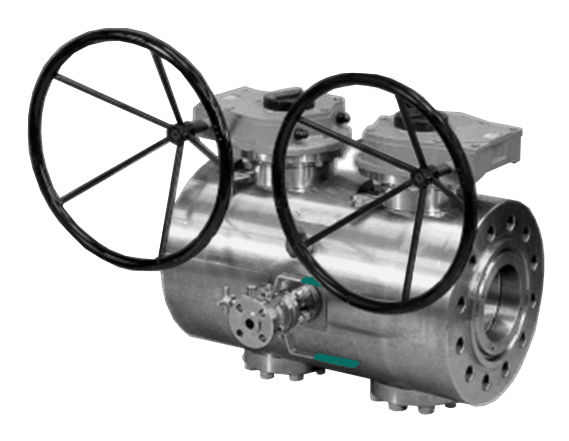

Twinsafe

Key features & Benefits

- Space-saving – ability to replace single isolate valves with a true double block and bleed valve, but within the same overall length, ensuring that expensive pipework modifications are kept to an absolute minimum.

- Weight-saving – compared to a conventional Double Block and Bleed hook up of two separate ball valves with a central spool piece and vent valve, weight savings can be over 50%.

- Increased Safety – compared to a conventional Double Block and Bleed arrangement using separate valves, the number of potential leak points is greatly reduced.

- Cost-saving – fewer items to purchase and expedite means overall cost savings, plus lower installation and maintenance costs.

OLIVER VALVES Resources

Soft-seated valves for Hydrogen applications

Hydrogen, being a volatile gas, poses substantial risks to the integrity of materials. Selecting appropriate materials becomes crucial to ensure optimal valve performance. Hydrogen embrittlement, a phenomenon where hydrogen atoms infiltrate the metal lattice, leading to brittleness and cracking, presents significant safety.

- Instrumentation valves for blue hydrogen reformation from fossil fuels and green hydrogen produced by electrolysis.

- Fluid control solutions for both post and pre-combustion carbon capture applications.